September 25, 2025

Beyond the Surface: Unlocking Systemic Insights Through Better Root Cause Analysis

When people are injured at work, investigations often rely on root cause analysis tools like the “5 Whys” or the “Ishikawa Fishbone” model to understand why the injuries happened and how to prevent them from happening again. While these methods can shine light on contributing factors, the way they are used tends to oversimplify complex situations, which can lead to a focus on individual errors and behaviors leading up to the injury. This leaves organizations with shallow insights and weak corrective actions, which do not effectively prevent similar incidents from happening.

The question we should be asking isn’t just what happened? We should also be asking what allowed this to happen?

Case Example: A SIF While Towing

A team performing their work remotely suffered a serious injury when a trailer they were towing got stuck in a ditch. Even before the accident, there were signs of trouble brewing when the driver stated he did not feel qualified or comfortable moving the equipment. After the trailer was stuck and while trying to recover it and the equipment, the equipment tipped over and pinned an operator. The investigation found “driver inexperience”, “driver’s poor approach to narrow bridge”, and “work procedure for releasing load” as root causes. Corrective actions included “driver probation”, “driver retraining”, and “update of loading/unloading procedure.” While this was a neat and tidy investigation resulting in corrective actions, it missed what truly allowed the injury to happen.

Moving Toward a Systems View

To understand what allowed the injury to happen, not just what triggered it, deeper systems-based approaches are necessary. Two approaches stand out for their ability to reveal dynamics that are otherwise often missed:

Applied Behavior Analysis (ABC Analysis)

This method systematically examines:

- Antecedents (what occurred before an event)

- Behaviors (actions taken)

- Consequences (outcomes)

In the towing incident, this approach reveals:

- While the driver made errors in his approach, even more important was that he had never been trained appropriately for the equipment he was towing.

- The strong “can do” culture influenced the protesting driver to proceed because of the opportunity to earn his certification and to avoid delaying the crew.

- Without meaning to, supervisors unintentionally incentivized unsafe choices.

These deeper insights reveal more than just what was done, they reveal why the behaviors occurred.

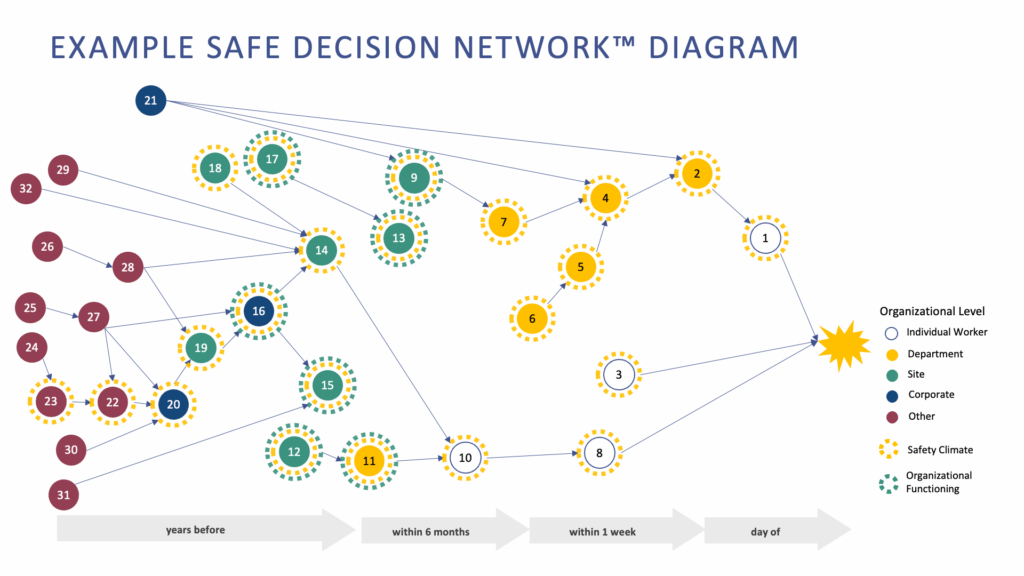

Decision Network Analysis

This approach creates a map of key decisions that were made over time, which helps us understand how risk accumulated.

In the same towing incident, we learned:

- The unloading procedures were created without sufficient input from people with hands-on experience working in a real-world context.

- A pattern of overconfidence was at play. Overconfidence in others was demonstrated when the driver said he was uncomfortable and preferred not to tow the equipment, but the supervisor insisted he could handle the new assignment. When the operator took control and attempted to unload the equipment himself, he was showing overconfidence in himself based on his past successes resolving similar situations.

The patterns revealed in the decision analysis show how everyday choices allowed risk to accumulate, finally culminating in this incident.

Rethinking Root Cause Analysis

To truly learn from incidents, organizations need to go beyond just identifying what went wrong and learn how the systems allowed it to go wrong. Reflecting on the equipment tip-over example, we can see the difference between a traditional approach and a more systems approach:

- Traditional Analysis: The driver and the operator both made mistakes and need retraining and/or disciplinary action.

- Systems Analysis: Examines how training gaps, deficient procedures, organizational/cultural pressures, and flawed decisions influenced the operator’s actions, and offers better insights into what needs to be remedied so a similar incident doesn’t happen again.

By embracing a systems approach, organizations can shift from reactive responses to proactive strategies that address real root influences, not just symptoms.

The Value of Deeper Learning

Systems analysis fosters a culture where leaders learn not just from the event, but also, from the factors that created the conditions for it. This transforms safety management from being a process of accountability to being about continuous learning and system improvement.

Progressive companies that have made the shift to a systems view of injury causation have experienced powerful improvements in reducing exposure to SIF events. If your root cause analysis process keeps pointing to people and conditions close to the time of accidents as the causes of incidents, now may be a good time to look into tools that challenge assumptions, uncover hidden risks, and can help you build a stronger culture of SIF prevention.

If you would like to talk to a Krause Bell Group Executive Consultant about building a stronger culture of SIF prevention, request a consultation